It was a blustery mid-December morning with temperatures in the low teens — just a day prior to a single digit temperature and a walloping New England winter storm — that we chose to visit a unique dairy farm. We all know that farming goes on year-round, though most would not think of visiting a dairy farm on such a frigid day.

Great Brook Farm State Park in Carlisle, Massachusetts, USA, encompasses about a thousand acres of protected lands with over twenty miles of trails for cross country skiing, biking, walking, equestrians, and nature lovers. It has been a home for the black-and-white dairy cows known as Holstein for over sixty years and is listed as one of the most scenic, historic farms in northern Massachusetts.

The signage for Great Brook State Farm can hardly be missed with its large painted black and white Holstein lady. Fields of hay, managed woodlands, wild flowers and corn grow along the farm roadways in the warmer seasons. A white New England farm house sits on a slight hill off of the main farm road and marks the entrance to the dairy farm portion of the park, where Tamma and Mark Duffy live and manage about 300 acres of a state-of-the-art demonstration dairy farm for the Massachusetts Department of Conservation and Recreation.

Behind the white farm house are red barns and traditional New England farm structures with silos and fenced pastures. Toward the back of the older buildings, a newer farm building can be seen. Designed to aesthetically fit in with the old farm flavor, this three-year-old structure does not outwardly appear to be any different from any other newer dairy barn.

Farmer Tamma, photographer Kathy Joyce, and I entered the building to walk down a long hallway and into a milking parlor area where several of the black-and-white ladies were peering at us over the tubular fenced entrance to the robotic milking system. Tamma explained that we had just missed the milk pick-up for the farm, and once the tanks were emptied, the automated system cleans the tanks, lines, and all milking equipment. Milk is picked up every other day for processing for this Cabot Creamery Cooperative Farm. With about twenty minutes more in the cleansing process, our farmer took us into the main portion of the barn.

About ninety Holstein dairy cows were freely walking around aisleways with open three-sided stalls for feeding or sleeping. The building was designed to hold comfortably about one hundred and twenty cows. The barn walls have pillowed clear plastic window shades with metal screening, which prevent birds from entering, and cover much of the length of the barn. The shades are part of the environmental-control system and were designed to provide the maximum amount of fresh air for the cows according to the temperature inside and outside of the building. They can adjust either by dropping downward from the top or lifting upward from the bottom and sometimes a combination of the two. Natural lighting and the solar heating of the fully-closed pillow shadings helped warm the building on our visit. Several large automatic fans – positioned and angled in just the right manner to help circulate the air without blasting the pine bedding everywhere – were stationary on this cold day. This automated environmental-control system manages the climate in the barn to keep the cows comfortable, productive, and healthy.

In keeping with “cow comfort,” floor mats with fresh pine shavings were in each sleeping area. Every cow had a well-bedded stall, and extra open bedded stalls were available for additional cows or for those ladies who might want to sleep in a new bed. A sample mat lay on the pedestrian floor for us to step on. The cushioning properties of this bacterial-resistant, non-permeable pad significantly reduces the need for conventional wood-shavings bedding materials and cleaning labor.

An automated slow-moving scraper moved across the aisle way, cleaning up as cows calmly stepped over it. The scraper was pulling the waste material into a grated area that opened to a collection pit below. This material would later be moved to a composting location, then used back on the land or sold to the public.

Each black-and-white lady wears a blue collar with an activity monitor that identifies her and collects her data 24 hours a day, transmitting this data wirelessly to the robotic dairy’s system controller. The unit tracks the cows as they walk, lie down, head to the feeding, watering, milking, or grooming locations. Additionally, it monitors how long or how often they visit a location. If a cow lies down longer than normal or if there are any other programmable alert requirements designated by the farmer, the farmer will receive a call and/or a system-generated text to alert them to that condition.

When it comes time for being milked, each cow in the Duffy herd chooses what time of day or night she wishes.

In the milking area cows are guided to the robotic milking system after a scanner reads the cow’s identity and matches it to her milking history. The robotic system is designed to take into consideration the milking cycle of each cow and determine just how often to milk her. The average cow gets milked three times a day, but it can range from two to four milkings depending on her needs. If the cow is approved to be milked, a gate to the robotic milker will open and the cow will proceed forward. If not approved to milk, another gate will open for direct access to the feeding area.

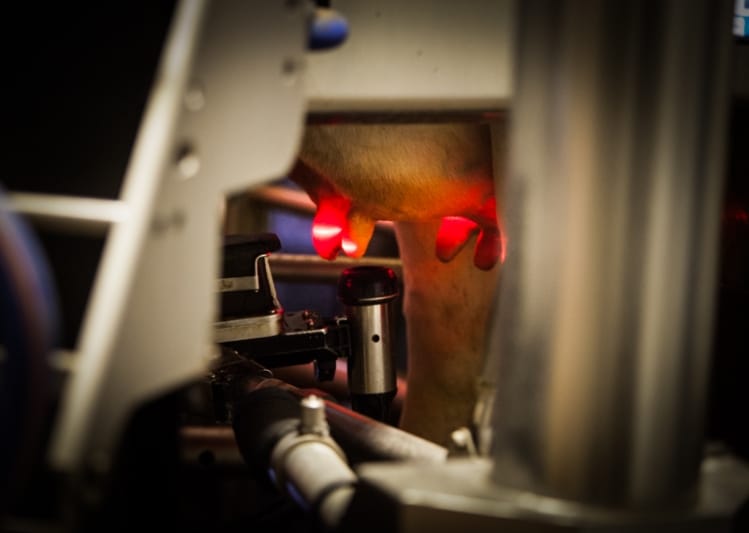

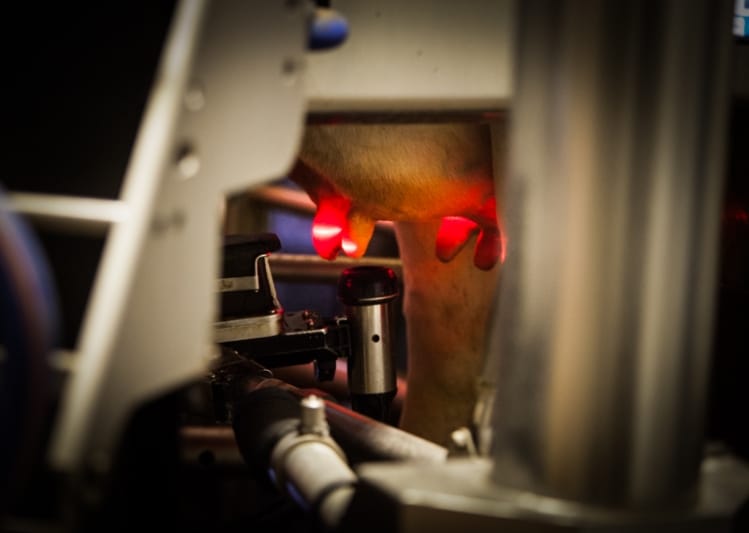

During the milking, the cow is automatically fed a very tasty snack as the process begins. First, the teats are cleaned by a misting of a cleansing solution, then rinsed and dried via a cleaning teat cup. A robotic arm efficiently attaches milking teat cups, using two lasers and a camera according to programmed settings for her teats. The teat settings are coded in the system the first time a cow is milked and updated each time she is milked. The milk is continuously monitored while the cow is being milked. If a problem is detected, the milk will be discarded and the system will wash and sanitize before milking another cow. The farmer is immediately notified of any issues by a call and an alert text. If the milk is fine, the process continues, and the milk is immediately cooled and stored in the refrigerated tank for the next dairy pick up.

In the milking area cows are guided to the robotic milking system after a scanner reads the cow’s identity and matches it to her milking history. The robotic system is designed to take into consideration the milking cycle of each cow and determine just how often to milk her. The average cow gets milked three times a day, but it can range from two to four milkings depending on her needs. If the cow is approved to be milked, a gate to the robotic milker will open and the cow will proceed forward. If not approved to milk, another gate will open for direct access to the feeding area.

When the milking process is completed, the robotic system removes each teat cup, then sprays each teat with a protective anti-bacterial solution. The exit gate opens for the cow to return to the herd. Before the next lady enters, the system quickly flushes each teat cup and cleans each line to protect the integrity of the collected milk and the health of the next cow.

When the Department of Conservation and Recreation wanted to upgrade the dairy demonstration portion of the farm, Tamma’s husband, Mark Duffy, suggested the DeLaval robotic milking system, manufactured by a 125-year-old Swedish company.

Mark wanted the public to see a state-of-the-art dairy operation that is unique in all of Massachusetts. It is a fascinating system to watch, even in the off season of winter.

You can take a quick online dairy tour of Great Brook Farm, view a DeLaval company video to see how the milking units work, or visit Great Brook Farm’s Facebook page. Currently the robotic system is not an inexpensive system to implement, though costs are declining as technology advances. It is not for every dairy farm but is designed for family farms like those found in New England.

Great Brook Farm State Park is open year-round with many seasonal activities listed on the park’s web page. Some activities need reservations, such as the dairy tour. Come in the warmer weather for the dairy tour, when the land is in bloom and the Duffy’s ice cream stand is open, and so that you can meet the Duffy family and their ladies. ![]()